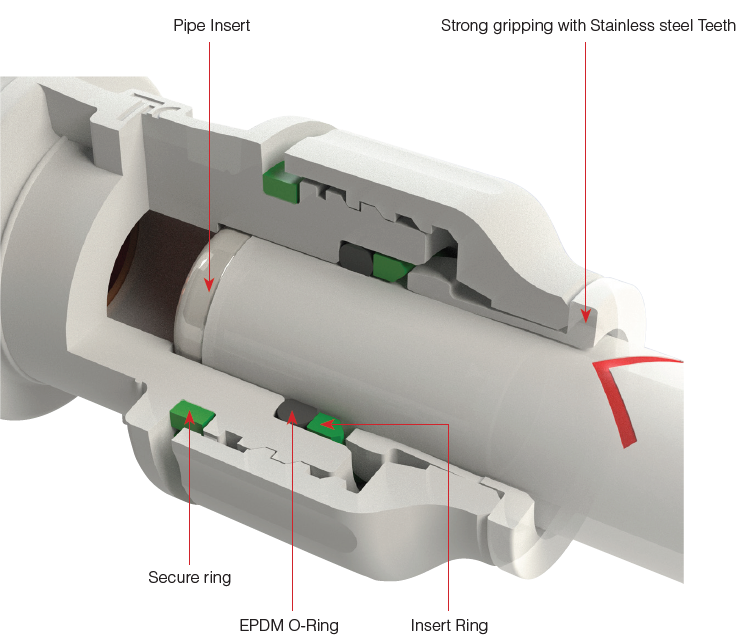

The technology in Twistloc® push -in fittings offers greater security and efficiency compared to other traditional fittings and valves , giving you the reassurance that the products you’re installing are built to last. All plastic fittings and valves can be designated with a visual colour connection , ensuring that the connection is secure. Twistloc®products are certified for use with PEX, PB, Copper and cPVC pipe , making it easy to combine different types of pipe for repairs or new installations. Our products are easy to install and can help save labour time substantially.

Twistloc® products are a one step, fully demountable and reusable push-fit plumbing system which combines both pushfit and twist locking technology to offer a guaranteed secure, peace of mind leak free joint. Twistloc® which incorporates pressure and combination system, is the Twist and Lock system suitable for plumbing, local/home hot water supply and heating systems. Twistloc® products have been tested and approved in accordance with WRAS, Kitemarked to BS 7291 Parts 1,2 and 3 Class S, cUPC,

NSF, Water marked to AS 4176.3 and ACS.

Our products provide for the perfect plumbing system and are manufactured to ISO 9001 BSI standard. The specification of products complied with the requirement of central local/home heating and water supply systems. Various test have proved that Twistloc® products are resistant to temperature and pressure beyond the normal operation ranges. The secure connection indicator means that once the green band can no longer be seen, you'll have absolute certainty that the joint is properly connected. This means you can be rest assured, knowing that you won’t have to worry about future issues with leaks due to imperfect joining. The secure connection indicator is patented by our manufacturer. Not only does it make installations easier and safer, but is also straightforward and simple to use. Twistloc® products must be installed to the correct plumbing regulations. Follow our installation guide for further information on correct fitting.

These instructions relate to the installation of Twistloc® fittings

for copper, PB, PEX and cPVC pipes.

Please note that it is the installer’s responsibility to ensure

that Twistloc® fittings, pipework and other components are appropriate for the intended applications, and that products are installed in accordance with the installation instructions and local plumbing codes.

No information in this publication is intended to create any warranty beyond the SNC product warranty applicable to the plumbing system.

Installing push-fit products:

Before you start, inspect the pipe. Ensure there are no scratches, gouges or any form of damage or deformation on the pipe. It should also be free from dirt and grease that may affect the seal.

Pay close attention to the first inch (25.4mm) from the cut

ends. Damage or foreign substances in this area may cause leakage problems. If there are any concerns, cut the affected pipe end to a clean and undamaged point.

Don’t use any coarse materials to clean the outside surface

of either plastic or copper pipes as this could affect the seal and result in leakage.

Ensure fittings and pipes are always kept clean by keeping

them in the packaging provided - don’t empty products

onto the floor.

Never insert your finger into the fitting as you risk being

cut by the metal ‘grip teeth’ inside the fitting.

| Working Temperatures and Pressures | |||

|---|---|---|---|

| NO. | Usual Temp | Max Temp | Pressures |

| Cold Water | 20˚C | 20˚C | 12 bar |

| Hot Water | 65˚C | 95˚C | 6 bar |

| Central Heating | 82˚C | * 114˚C | 3 bar |

* Short term overload of up to 114°C

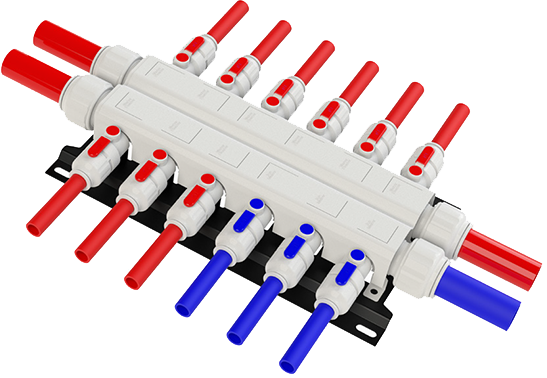

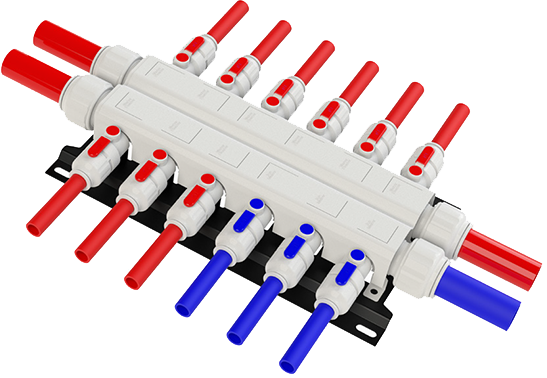

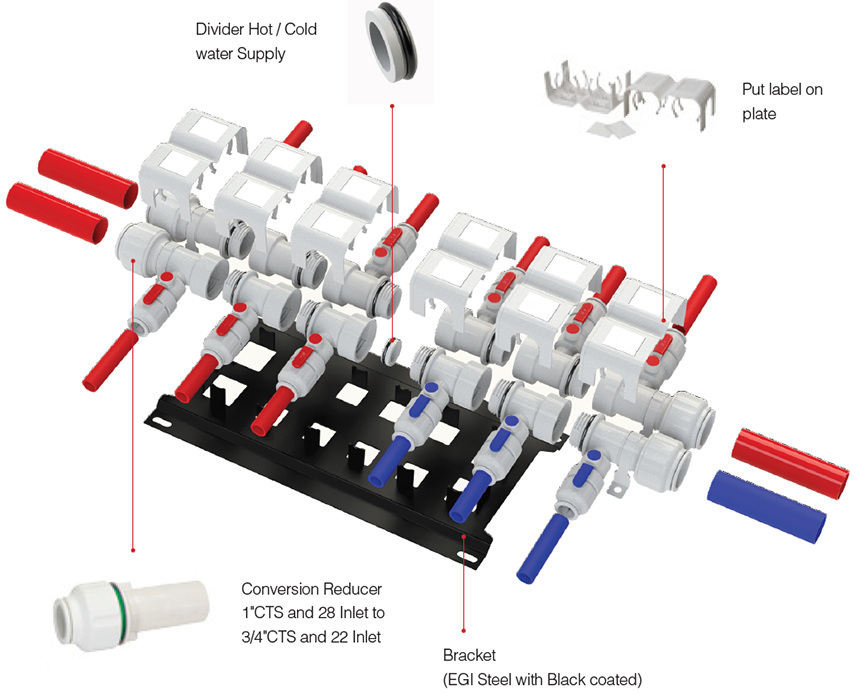

Twistloc® Manifolds combine push-fit technology with the value-added advantages of a manifold.

Twistloc® Manifolds are designed to simplify manifold and pipe installation in Copper, cPVC, PE-RT, PB and PEX pipe, water or hydronic heating systems.

Twistloc® manifold control unit being tested to requirements of IGC109 and approved in NSF/ANSI 372 Twistloc® manifold supply inlet connections utilize a special 1"CTS or 28 OD connection that requires transition fittings. Connections for the individual pipe distribution lines are push-fit type of fittings. Use only fittings supplied with Twistloc® or other fittings designed for special port transitions which are available from your Twistloc distributor.

In order to maximize the maximum water and energy savings of Twistloc® manifold system, it is recommended to use the smallest distribution line Size that satisfy the flow rate and pressure requirements of each individual fixture. Using lines in Sizes larger than necessary can increase hot water delivery time.

Measures such as: increasing the line Size up to 1/2"(15), relocating the Twistloc® manifold to reduce line length(s), installing a separate Twistloc® manifold close to an outlying group of fixtures, or running the line(s) in a more direct (shorter) path may alleviate a potential problem.

If the hose bibbs are primarily for irrigation purposes, they should be supplied from the main service line prior to Twistloc® manifold. The service line should have Sizes appropriate for the additional water demand.

Typical Supply line size: All inlets are 1”CTS(28mm) and use a reducing stem connector to create other inlet sizes.

Typical Distribution line size: 1/2″ CTS (15mm)

| Working Temperatures and Pressures | |||

|---|---|---|---|

| NO. | Usual Temp | Max Temp | Pressures |

| Cold Water | 20˚C | 20˚C | 12 bar |

| Hot Water | 65˚C | 95˚C | 6 bar |

| Central Heating | 82˚C | 105˚C | 3 bar |

These Installation Instructions contain information on the installation of Twistloc® Manifolds hot/cold potable water distribution system Copper, cPVC, PE-RT, PB and PEX pipes.

The installer shall be responsible for ensuring that Twistloc® Manifolds, PEX tubing and other components on hand are appropriate for the intended applications, and that Twistloc® Manifolds are installed in accordance with these installation instructions and local plumbing codes.

Nothing in this publication is intended to create any warranty beyond SNC’s warranty applicable to Twistloc® manifold plumbing system.

NOTE: These instructions should be used to install Twistloc® Manifolds. Instructions specific to Manifolds will be contained in an instruction sheet provided with Twistloc® Manifolds.

Twistloc® Slip Connectors are designed to be suitable for Copper, cPVC, PE-RT, PB and PEX pipes. Twistloc® connectors offer the lowest material cost. When you need to repair a pipe line, Twistloc® slip connectors offer greater efficiency than traditional fittings.

Please note that it is the installer’s responsibility to ensure that Twistloc® fittings, pipework and other components are appropriate for the intended applications, and that products are installed in accordance with the installation instructions and local plumbing codes.

| Working Temperatures and Pressures | |||

|---|---|---|---|

| NO. | Usual Temp | Max Temp | Pressures |

| Cold Water | 20˚C | 20˚C | 12 bar |

| Hot Water | 65˚C | 95˚C | 6 bar |

| Central Heating | 82˚C | 105˚C | 3 bar |

(1) Ensure that the damaged pipe iskept clean

(2) Cut the damaged pipe less the instructed length ‘C’ shown in our specification.

(3) Connect the slip port with the pipe first and slide it until the connection is adjusted with the opposite side.

(4) Connect to the other pipe and arrange the connection position.

Twistloc® Stop & Faucet Valve Adaptor valves and Slip Tee Valves are manufactured in white Polypropylene, reinforced plastic which provides value added advantages in the installation of water supply line mainly. Twistloc® Stop & Faucet Valve Adaptors and Slip Tee Valves are designed for use in drinking water systems, Refrigerators, Ice-Makers, Humidifiers and Water filtration applications, etc.,. Our valves offer greater efficiency than any traditional valves.

Please note that it is the installer’s responsibility to ensure that Twistloc® fittings, pipework and other components are appropriate for the intended applications, and that products are installed in accordance with the installation instructions and local plumbing codes.

* Conversion adaptor can be assembled with 1/2" x 1/2" NPS , BSP or 3/8" x 3/8" Compression,BSP

| Working Temperatures and Pressures | |

|---|---|

| Usual Temp | Pressures |

| 1˚C | 10 bar |

| 20˚C | 10 bar |

| 65˚C | 7 bar |

(1)Shut off your existing Stop valve and disconnect the riser from the valve.

(2)Connect our Stop valve to the water valve.

(3)Connect the riser to our valve.

(4)Push fitting onto the end of the pipe until it reaches the pipe stop. Twist the screw cap until the coloured ring is no longer visible.

(5)Pull the pipe away from the fitting to check it is a secure fit.

(6)Test system to ensure watertight.